history

Founded in 1927 by Giuseppe and Bruno Bambi, La Marzocco had its beginnings in Florence, Italy, birthplace of the Italian Renaissance and home to such geniuses as Leonardo da Vinci, Michelangelo and Brunelleschi who created some of the most celebrated works of art in the world.

It seems only fitting that La Marzocco would earn a world renown reputation for making beautiful, high quality, superbly crafted and uniquely designed espresso machines, with great attention to detail.

In 1939, it was La Marzocco that developed and patented the first coffee machine with a horizontal boiler, now an industry standard.

This was the first of a series of important innovations, later to include the dual-boiler system with saturated brewing groups. Tradition and a passion in the search for quality and superior reliability are factors which have always distinguished and interested the entire company.

Even today, highly specialized personnel supervise each stage in the production of every single machine, hand-crafted to order for each and every client. In this way, Giuseppe Bambi’s great experience and professional pride live on after over ninty years.

For La Marzocco’s full history, click HERE

today, la marzocco remains an artisan company, while offering important advancements in equipment technology to its customers and in the industry.

1927 - 1929

fiorenza & the beginning

Originally named Officine Fratelli Bambi, La Marzocco is founded in 1927 by brothers and craftsmen, Giuseppe and Bruno Bambi, for the purpose of making their own brand of coffee machines.

The first machine, the Fiorenza, was designed by and commissioned on behalf of Mr. Galletti, who later abandoned the designing of espresso coffee machines.

il marzocco

Florence was consecrated, since the time of the Romans, to the god of war “Mars” whose name gradually evolved due to the popularization of the name, into “Marzocco”. With the advent of Christianity, the role of the defining city, traditionally attributed to “Marte”, was transformed into the heraldic symbol of the Lion, which became the iconographic symbol of the free republic of Florence and thus the name of “Marzocco”.

La Marzocco bears its name from the heraldic lion, sculpted by Donatello in 1418-1420. The lion is seated and with one paw supporting the coat-of-arms of Florence, il giglio, the lily.

Just as the Marzocco statue represented the conquest of neighboring lands at the time of the Florentine Republic, the Marzocco would symbolize the company’s winning strategy every time a machine was designed, manufactured and sold. Indeed, at a time when few people drank coffee and even fewer shopkeepers were willing to invest in a machine for a beverage that could not be defined as popular, each sale was a success.

For this reason, Giuseppe and Bruno Bambi adopted the image of the Marzocco for the company, a symbol of victory and conquest, the symbol of Florence.

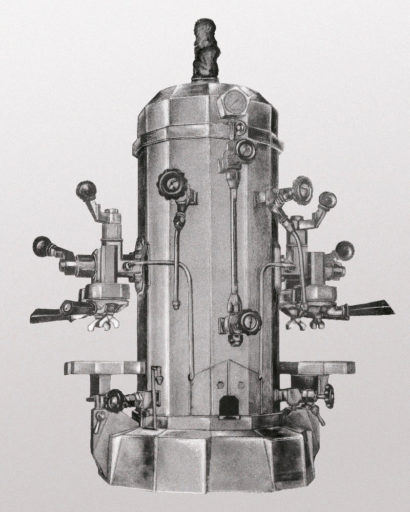

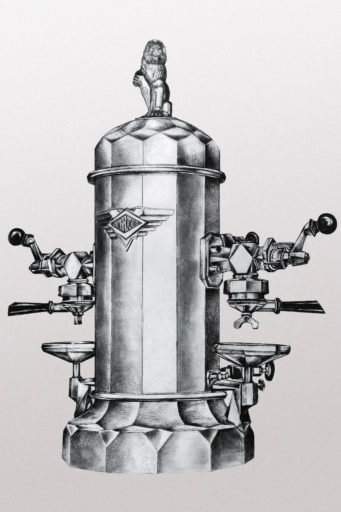

la marzocco | 1927

Designed and manufactured by Giuseppe Bambi for the first “La Marzocco” machine, with two groups and a vertical boiler. Polygonal body with 12 faces. The upper cap bears the bronze-cast “Marzocco” symbol. Functioning: hot water and steam pressure, generated by a vertical boiler, distributed on ground coffee by a 3-way tap.

The tap, working by rotating a hand lever, was placed on the group’s body. When the machine was not used, the tap allowed for the release of the pressure created in the filter-holder during coffee brewing.

Estimated production: 30-35 units.

1930 - 1939

la marzocco | 1930

Four groups and a vertical boiler. Polygonal body with 12 faces. The upper cap bears the bronze-cast “Marzocco” symbol.

Functioning: hot water and steam pressure, generated by a vertical boiler.

Estimated production: 8-10 units.

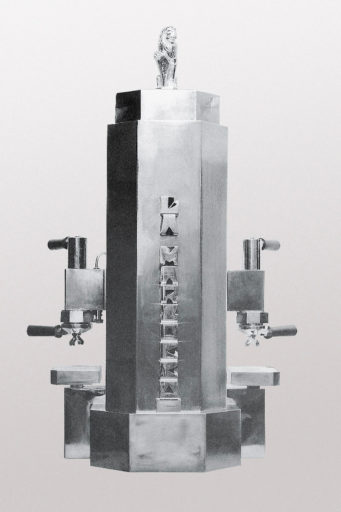

la marzocco | 1934

With the arrival of Fascism, the consequent winds of change become reflective in decorative styles. La Marzocco, while continuing to produce machines with a vertical boiler, begin to design machines with more linear and essential shapes.

Two groups and a vertical boiler. Irregular polygonal body with 6 faces. The “La Marzocco” vertical writing in cubiform letters and lion are on the upper cap.

Functioning: hot water and steam pressure, generated by a vertical boiler. The group bodies were reshaped and suited to the aesthetics of the machine, which is more linear and conforms to the new style of design, which was much simpler in its drawing.

Estimated production: 35-40 units.

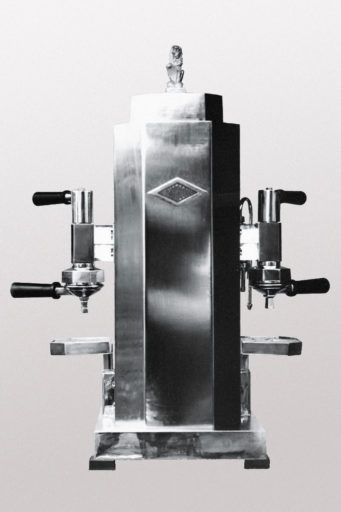

la marzocco | 1935

Two groups and a vertical boiler. Irregular polygonal body with 6 faces and a square base. The upper cap bears the bronze-cast “Marzocco” symbol.

Functioning: hot water and steam pressure, generated by a vertical boiler.

Estimated production: 25-30 units.

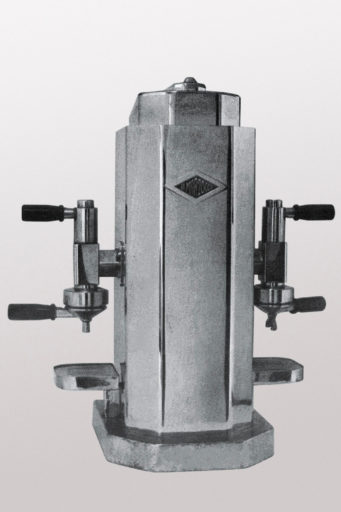

la marzocco | 1936

Two groups and a vertical boiler. Square base. The upper cap bears the bronze-cast “Marzocco” symbol.

Functioning: hot water and steam pressure, generated by a vertical boiler.

Estimated production: 20 units.

la marzocco | 1938

Two groups and a vertical boiler. Irregular polygonal body with 6 faces.

Functioning: hot water and steam pressure, generated by a vertical boiler which could be kept at a consistent temperature by means of an electric element, gas stove or charcoal stove. The lion was removed to allow for the “draught” of the coal stove from the upper cap. Subsequently, to make the lion less expensive (especially given the difficult pre-war times), a new aluminium-cast lion was designed and realized, and was stylized to suit the linear and essential body of the machine.

Estimated production: 15-20 units.

fruit juicer | 1938

Citrus fruit squeezer from the late 1930s. The Bambi brothers’ creativity extends beyond espresso coffee machines, to include – from time to time – the design and manufacture of equipment.

marus | 1939

The growing consumption of espresso type coffee results in the need to simplify and improve machine design. On February 25th, Giuseppe Bambi registers patent number 372525 for the first espresso coffee machine with a horizontal boiler. Unfortunately, while La Marzocco has no specimen or photos of this machine, the company archives hold the signed copy of the patent together with the original aluminium-cast blue-prints from which an image has been re-created.

1940 - 1949

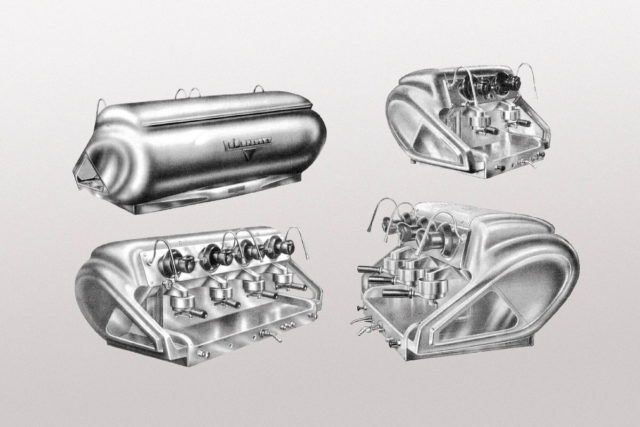

eureka | 1947 – 1950

Designed by the Bambi brothers in the immediate aftermath of the Second World War.

Functioning: pressure of hot water and steam generated by a horizontal boiler which had – by then – become commonly used by all manufacturers (the patent had been forfeited as it was not renewed because of the war). Notable technological development of the mechanical system of distribution of the 3 water tracts (water, steam and drain). The mechanical valves were started by pushing two concentric buttons, which already had a very ergonomic design.

Estimated production: 600-700 units (2, 3 and 4-groups).

1950 - 1959

alfa trolley | 1950

Designed for hotel restaurants. Designed by Giuseppe Bambi, this trolley makes it possible to serve coffee and after-dinner drinks, table side. It was equipped with a La Marzocco 1-group Eureka series machine.

Estimated production: Unfortunately, due to a poor marketing campaign, only a few units were produced. The idea, however, to brew espresso coffee directly before customers at their table was quite innovative.

national | 1951-1952

Functioning: La Marzocco introduces its version of the lever machine, which utilizes a spring that acts on a piston pressing water through the coffee at approximately 14 atmospheres. This changes the traditional system of the extraction of coffee, as well as the taste and, and in light of the pressure typical of lever machines, “crema” appears on top of the extracted espresso for the first time.

Estimated production: 150-200 units (2-group).

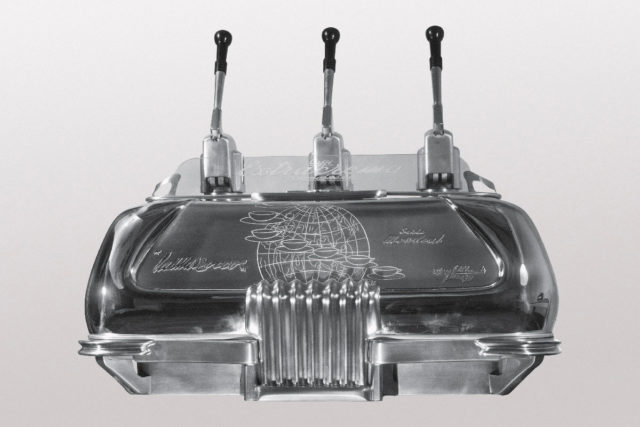

mondial 1° series | 1951-1952

The Mondial represents the introduction of the globe logo, which is etched on the machine’s stainless steel body. The artwork is characterized by the diagonal “ring of coffee cups” that extend around the Earth.

Functioning: lever machine.

Estimated production: 100-150 units (3-group).

mondial 2° series | 1951-1952

Functioning: lever machine.

Estimated production: 30-35 units (4-group).

rondine | 1953

This 1-group machine was part of the first series of lever machines and was produced together with the 2, 3 and 4-group National and Mondial machines. The Rondine would soon be replaced by the Comet model, which was more suitable for standardized production.

Functioning: lever machine.

Estimated production: 400 units (over a 5-year period).

multiple group fruit squeezer, mixer & ice-crusher | 1954

This extremely versatile accessory for bars was equipped with three motors and was one of the first mixers equipped with crystal glasses and stainless steel blades, at a time when mixers were made of glass and blades of brass.

For this reason, it became known as the Hygenic Beverage Mixer.

Estimated production: 100 units.

aurum | 1954-1955

Functioning: La Marzocco creates an automatic hydro-compression machine. The Aurum automated the lever action. Connected to a ratiomotor started by an electric motor, the lever automatically lifted the piston, bringing the spring to the potential state. Simply put, the brewing-piston was lifted and pressed during brewing by means of a motor-driven piston whose surface was 6 times bigger and was started by the pressure of steam generated by the boiler (thus turning the 1.5 atmospheres of pressure inside the boiler to 9 atmospheres of pressure on the brewing piston).

Estimated production: 100-120 units (3 and 4-group)

alba | 1954-1955

Functioning: automatic hydro-compression machine. The Alba’s unique body, allowed it to be partially built into the bar counter so as to use its upper surface (the current cup-warmer) as a support on which to serve coffee to customers.

Estimated production: 60-70 units (3 and 4-groups).

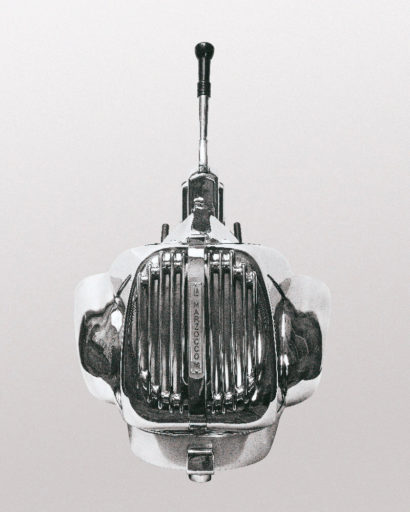

disco volante | 1954-1960

With its futuristic design, Disco Volante is the Italian translation of “Flying Saucer”

Functioning: espresso coffee grinder-doser which left practically no trace of coffee between the grinders or in the ground coffee container.

Estimated production: 200 units.

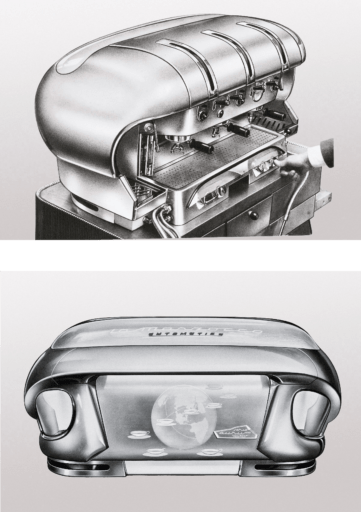

olimpia | 1956-1958

With the Olimpia series, the globe logo evolves in design as the ring of coffee cups is replaced by the company’s name, “La Marzocco”.

Estimated production: 300-450 units (2, 3 and 4-groups).

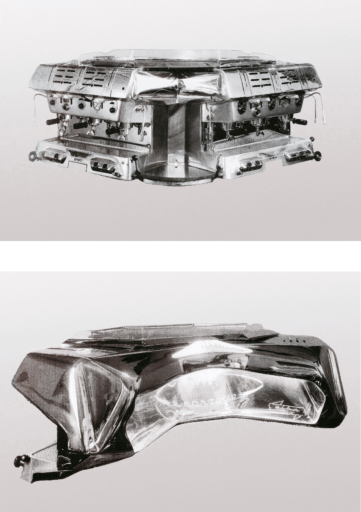

3+3 | 1957

Custom 6-group machine that was designed to be placed in a corner as if to “embrace clients”.

Functioning: automatic hydro-compression machine.

Production: 1 unit. The 3+3 was installed in the Bar Bruzzichelli in Piazza Duomo, in Florence.

crema-espress | 1958-1960

Also called the Micromarzocco, this espresso machine was designed for domestic use.

Functioning: this lever machine was created with an electric heating element or made available for use with a “spirit stove”.

Estimated production: 100 units (1-group).

1960 - 1969

etruria | 1960-1963

Functioning: automatic hydro-compression machine.

Estimated production: 500-600 units (2, 3 and 4-groups).

comet | 1961-1968

Functioning: lever machine.

Estimated production: 500 units (1-group).

poker | 1964-1970

Functioning: automatic hydro-compression machine.

Estimated production: 1,600-1,800 units (1, 2, 3 and 4-groups).

vulcano | 1968-1980

In 1968, Giuseppe Bambi’s Vulcano was awarded the Decorative and Industrial Arts Prize on occasion of the 14th Triennale di Milano exhibition.

Functioning: espresso coffee grinder-doser featuring a micrometric grinding adjustment.

Estimated production: 450 units.

1970 - 1979

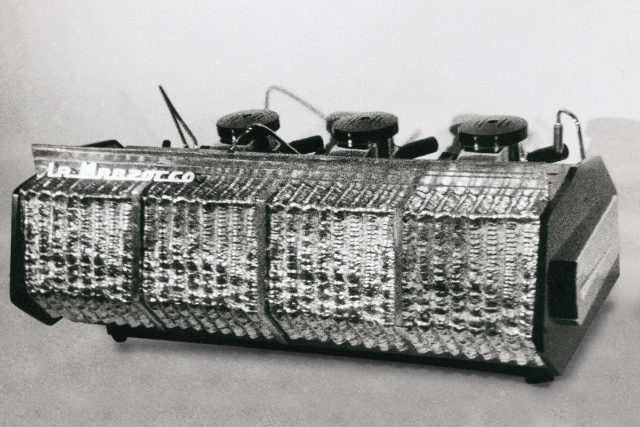

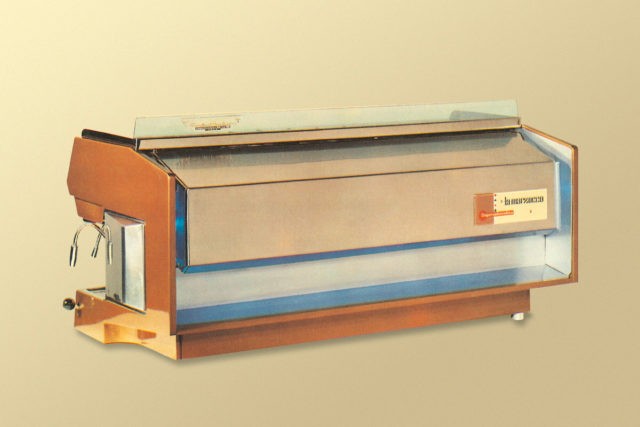

gs | 1970-1981

gs | 1970-1981

La Marzocco begins the production of the new GS series, which incorporates two important industry innovations: the use of independent boilers which isolate coffee brewing from steam and hot water production along with saturated groups. Both innovations vastly improve the thermo-stability of the machines. The letters “GS” stand for “gruppo saturo” or “saturated brewing groups”. While one boiler is used to generate hot water and steam (to make tea and froth milk), the other is dedicated to brewing espresso coffee. All La Marzocco equipment, from the introduction of the GS model, are equipped with the “dual” boiler and saturated brew group technology.

Functioning: automatic hydro-compression machine. Different versions with different starting systems were later produced – both manual and with solenoid valves. In the latter case, brewing could take place by means of an on-off switch or could be controlled by a timer.

Estimated production: 2,200-2,400 units (1, 2, 3 and 4-groups).

gs urania | 1974

With its front panel designed in bright Murano-glass, the GS Urania was built on the GS platform (2nd series).

Production: 1 unit.

small | 1978-1980

This machine, with its compact footprint (30x30x40cm), was the smallest machine produced by La Marzocco until 1980.

Functioning: equipped with two boilers and designed for semi-automatic (continuous) brewing only, it was created for counter surfaces with very limited depth.

Estimated production: 50 units.

1980 - 1989

gs2 | 1970-1981

In the early 1980s, La Marzocco redesigned the body of the GS model. This led to the creation of the GS/2 series. The GS/2 functioned very similarly to the original GS. During the mid-1980s, automation became a key feature for traditional espresso machines, especially to regulate the quantity of brewed coffee in the cup. In fact, one early solution was to integrate timers in order to control the brewing time.

Part of the GS/2 series, the groups of this semi-automatic (continuous) machine were no longer exposed, rather they became covered and housed within the body. Different models were created, of which the last one paved the way for the volumetric dosage as opposed to automatically dosing brewed coffee with a timer.

gs2 limited brass edition | 1986

This machine featured a custom brass body and was produced using the same chasis and mechanical components used in the GS/2. Further to this, this limited edition model featured a spoiler that provided a second rack to store and warm porcelain cups.

Production: 3 units, all manufactured for the same client in Florence.

1990 - 1999

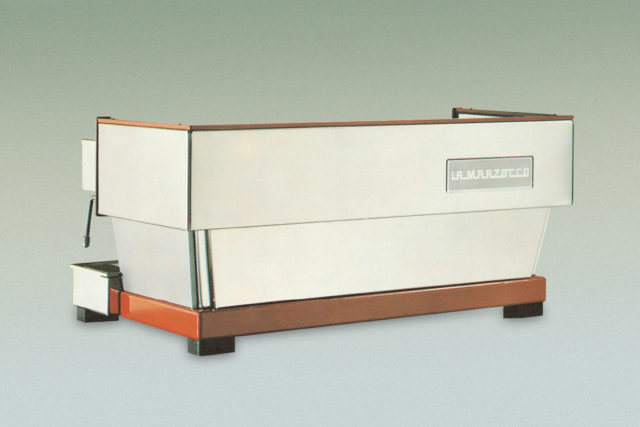

linea red series | 1990-1993

The Linea series of machines is introduced, including standard thermo-stability features with a classic stainless steel body design that remains popular today. The original series was made in stainless steel with a red colored frame. The Linea was built on the GS/2 platform, and was available with solenoid valves and on-off switches or with automatic volumetric dosing for brewed coffee.

Estimated production: 1,200-1,500 units (1, 2, 3 and 4-groups).

linea limited brass edition | 1992

This machine featured a custom brass body and using the same chassis and mechanical components used in the Linea.

Estimated production: 5 units (3-group) and 3 units (4-group) units, custom-made for a select group of important clients in Florence, Rome and abroad.

linea classic | 1993

Designed like the original Linea, but with a black colored frame, the new version introduced a series of new components.

Production: thousands of Lineas have been produced and sold around the world. It is the Linea, more than any other model, which identifies the company and the La Marzocco brand. The Linea is still produced today.

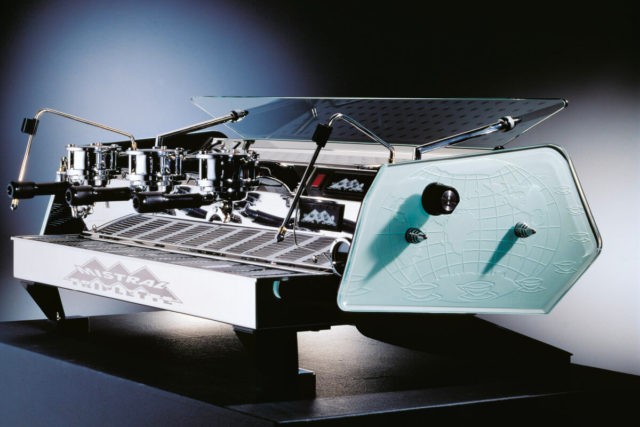

mistral | 1995-2004

This machine was designed to be a modern version of the previous GS machine. It was created by Dutch designer Kees Van Der Westen and introduced at the HOST Expo in Milan. The La Marzocco logo was originally sand-blasted on the glass side panels.

Functioning: same as the Linea. Production: 116 units.

fb70 | 1997

Celebrating La Marzocco’s 70th anniversary, a later version of the Linea, that is equipped with an elegant body that can be produced in virtually any colour, is introduced as the FB70.

Production: thousands have been produced and sold around the world.

2000 - 2009

swift | 2000

La Marzocco introduces the Swift grinder at the SCAA conference in San Francisco. This patented device is the first espresso grinder to incorporate direct grind and dosing into the portafilter along with automatic tamping. The Swift is awarded “Best New Product” of the conference.

Production: a few thousand Swifts have been produced and sold around the world. The Swift grinder is still produced today.

mistral new version | 2005

This new version of the previous machine model, is also designed by the famous designer Kees Van Der Westen, though it is manufactured at the La Marzocco factory. With respect to the previous model, the new version encompasses the technology of the FB80 and GB5, making the machine both unique in its design and representative of La Marzocco’s most sophisticated technology.

Production: The Mistral is manufactured upon client request only, a maximum of a couple of dozen a year with an open waiting list.

gb5 | 2005

The GB5 is first introduced during the HOST Expo in Milano in 2005 and launched at the SCAA conference in Seattle. This model introduces more sophisticated electronics and improved thermo-stability, along with an updated stainless body, which was entirely designed by Piero Bambi. The GB5 is named after Piero’s wife, Giovanna Bambi. When compared to previous models, it includes many technological advances, among which a pre-heating system and PID (Proportional, Integral, Derivative).

Production: thousands of GB5s have been produced and sold around the world. The GB5 is still produced today.

fb80 | 2006

Manufacturing the first unit for the World Barista Championships Finals in Bern, the FB80 was designed by Piero Bambi. Equipped with a customizable panel, the FB80 was named to commemorate the company’s 80th anniversary.

Production: thousands of FB80s have been produced and sold around the world. The FB80 is still produced today.

gs3 | 2007

The GS3 is introduced at the HOST Expo in Milan.

This compact machine, which aesthetically recalls the legendary GS series, features the same technology used in the GB5 and FB80.

strada | 2009

La Marzocco creates another industry first and launches the Strada with its pressure profiling technology on display in Atlanta at SCAA in April 2009.

The Strada, whose design was also based on input by a team of experts in the industry, allows the barista, for the first time, to have absolute and direct control over pressure at any given point during an extraction.

vulcano | 2009

A new family of espresso coffee grinders that bring together La Marzocco’s distinct design with Mazzer technology. Piero Bambi took inspiration from his father’s original Vulcano grinder and carried it into the 21st century. The Vulcano was introduced at La Marzocco’s first Out of the Box event in Milan in October 2009.

2010 - 2015

linea pb | 2013

Designed by and named in recognition of Piero Bambi, the Linea PB is launched in the USA and London in the Spring. Reminiscent of the Linea Classic, the Linea PB features flexible, user-friendly, exclusive proprietary, interface software and related hardware ideated by La Marzocco.

vulcano swift | 2014

The Vulcano Swift grinder was introduced in early 2014 with the Vulcano design and incorporating the Swift features such as the adjustable grind, dose and tamp technology, repeatability and consistency, high control level and minimum waste.

linea mini | 2015

The company launches the Linea Mini for the home. Born from the most iconic commercial espresso machine, the Linea Classic, the Linea Mini is equipped with a dual boiler, a pre-programmed pre-infusion feature and is optimised for the home in light of a built-in water reservoir, standard appliance power needs and its countertop footprint.

2015 - 2020

auto brew ratio | 2015

auto brew ratio | 2015

Continuing to innovate, Auto Brew Ratio was also introduced in 2015. An option on the Linea PP, this patented scale technology enables the barista to program and dose based on weight.

osmo | 2015

osmo | 2015

2015 brought La Marzocco Osmo, the Reverse Osmosis 3- stage treatment water system allowing one to brew a superior espresso and keep equipment in ideal working condition regardless of local water quality. It was available from 2015- 2018.

strada av | 2015

strada av | 2015

That year the Strada family was joined by the Strada AV, giving repeatability and familiarity in high-volume settings with barista friendly electronics which included a Performance Touch Steam Wand.

leva | 2017

leva | 2017

On La Marzocco’s 90th anniversary in 2017 the highly anticipated Leva, a ground-breaking model reinventing the technology and design of a lever-actuated espresso machine like never before, made its debut; first with an eye-catching 90th edition, later with the Leva X and Leva S models.

KB90 | 2019

KB90 | 2019

The first ever revolutionary Straight-In Portafilter was introduced on the KB90. Easing the workflow of busy barista. This innovative feature eliminated the bayonet-ring twist, thus reducing a common injury called Barista Wrist by a factor of 12. The KB90 featured a Drip Prediction Algorithm and the first of its kind: Group Steam Flush. Automatically bursting steam and a flush of hot water through the grouphead thus eliminating the need to backflush after each extraction.

2020 - 2025

GB5 | 2020

GB5 | 2020

With a history dating back to 2005, the second generation GB5 carries on the spirit of the GB5 line: a machine rooted in classical European design, coupled with cutting edge performance. The new GB5 S features a revamped visual identity which modernizes the machine without sacrificing the look, premium feel, or dynamic elegance.

The GB5 X is designed with traditional European style and is dedicated for those locations with an eye on classic aesthetics but that still demand the highest level of performance.